Room integrity & testing:

The objective is to save energy long-term, prevent structural damage, and continuously maintain a fire-safe protection level when an Oxygen Reduction System is in use.

The room integrity value is stated in the N50 value. It can be defined as the resistance to inward or outward air leakage through unintentional leakage points or areas in the building envelope

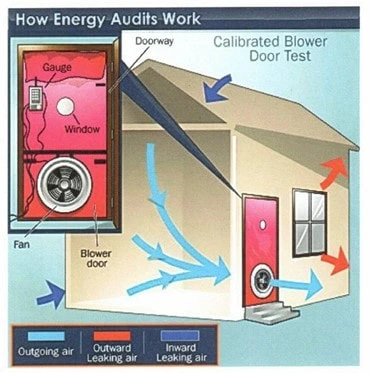

With the blower door test, the air tightness of a building is measured. The leaks in the building are determined

by leakage detection and can be corrected by the client later. New buildings should be erected with the required

room integrity value already in mind. The blower door test is the standard method for testing the air-tightness of a building.

The integrity value (N50) is determined by exposing the area to 50 pas over and 50 pa under pressure.

The blower door test is no longer performed only in the new dwellings but also includes large buildings such as warehouses, office buildings, cold stores, archives, gyms, or consumer markets to the standard of a construction project.

Objective:

The objective is to save energy long-term, prevent structural damage, and continuously maintain a fire-safe protection level when an Oxygen Reduction System is in use.

The room integrity value is stated in the N50 value. It can be defined as the resistance to inward or outward air leakage through unintentional leakage points or areas in the building envelope.

Room integrity:

The number of air-exchanges (N50 value) determines largely the required amount of nitrogen when the fire prevention method of Oxygen Reduction is envisaged.

Therefore a low N50 value should be aimed at as this:

- reduces the investments

- reduces the energy consumption & subsequently costs

- reduces the ORS plant dimensions

- keeps running costs low

- reduces running time of the ORS equipment

- extends lifetime of the machinery

Recommendations:

Wall insulation:

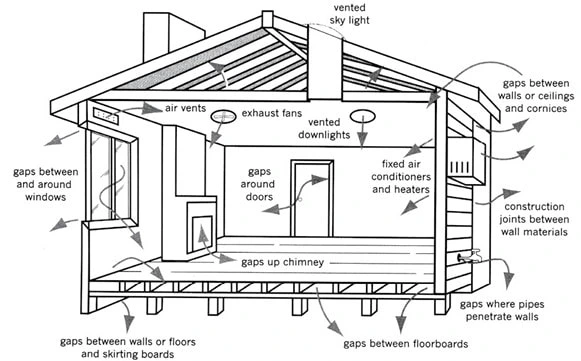

A wall in an existing building can be air-tightly insulated by different means, one method could be to seal the wall by applying sheets of plasterboard. Once the gaps have been grouted the wall will be airtight.

However, in many cases a coat of paint is sufficient. For this purpose, ISOLCELL has developed “ISOLCOAT” a special coating.

ISOLCOAT is a nontoxic and waterproof resin used as an internal coating for achieving gas tightness.

Due to its resilience, ISOLCOAT gives excellent results. It is the most popular gas-sealing product in this field.

ISOLCOAT can be applied to masonry walls, polystyrene, or sandwich insulation panels.

Door tightness:

In many buildings even doors with a circumventing rubber seal provide a gap on the floor which represents an unwanted leakage. To remove this leakage the installation of a simple door sill fitted with a cellular rubber facing the door leaf provides a perfect solution.

Airtight power socket:

In newer buildings very often the electrical installation is done by fitting cables through conduits. In those cases the power socket represents an unwanted leakage. To remove this leakage the installation of airtight power sockets is recommended.